Protecting your cherished guitar is paramount, and while commercially available cases offer excellent protection, they often come with a hefty price tag. Building your own DIY guitar case is a surprisingly accessible and rewarding project, allowing you to craft a custom-fit solution tailored to your instrument’s specific dimensions and aesthetic preferences. This approach not only saves money but also provides a unique sense of accomplishment, allowing you to personalize your guitar’s carrying case to match your individual style. You'll be amazed at how simple it is to create a robust and protective case for your prized possession.

This guide offers a straightforward, step-by-step approach to building a functional and attractive DIY guitar case, even if you're a complete beginner in woodworking. From selecting the right materials to the final finishing touches, we'll walk you through each stage of the process, ensuring you end up with a case you'll be proud to own and use. Let's get started with the first step in this fulfilling project.

Preparation and Safety Guidelines

- 3/4 inch plywood

- Miter saw

- Table saw

- Screws

- Wood glue

- Roundover bit

- Orbital sander

- Wood filler

- Upholstery foam

- Sharp knife or rotary cutter

- Spray adhesive

- Tolex

- Velvet

- Hinges

- Corner pieces

- Handles

- Latches

- Always wear safety glasses when using power tools like saws and drills. Wood dust and flying debris can cause serious eye injuries.

- Use clamps to secure your wood pieces during gluing and assembly. This prevents shifting and ensures a strong, even joint. Improper clamping can lead to weak joints and a damaged case.

- Sharp tools like chisels and knives require careful handling. Always cut away from your body and use a cutting mat to protect your work surface.

Step-by-Step Instructions

Cut and Assemble the Case Body

- Cut plywood pieces for the case sides and ends using a miter saw and table saw.

- Assemble the box using glue and screws, ensuring screws are placed consistently for later cutting.

- Cut the box in half using a table saw.

Cut and Assemble the Case Body Create and Attach Top and Bottom

- Create the top and bottom using 1/8 inch plywood, gluing and screwing them to the box.

Create and Attach Top and Bottom Smooth and Finish the Wood

- Round over all corners using a roundover bit and smooth with an orbital sander.

- Fill screw holes and gaps with wood filler and sand smooth.

Smooth and Finish the Wood Prepare the Interior

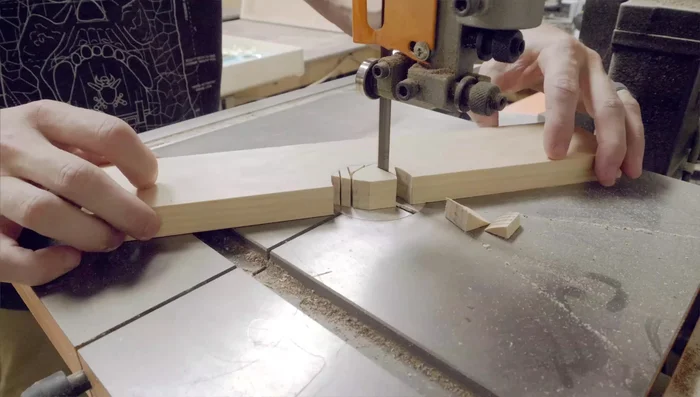

- Cut a slot for the neck using a bandsaw and trim for a snug fit. Account for added interior padding.

Prepare the Interior Line the Interior with Foam

- Line the inside of the case with 1-inch upholstery foam, cutting to wrap around the guitar.

Line the Interior with Foam Cover with Tolex

- Cover the case with Tolex using spray adhesive. Apply adhesive to both surfaces, let dry, and then adhere. Work in sections for best results.

Cover with Tolex Line with Velvet

- Apply velvet to the foam lining using spray adhesive. Work carefully to avoid wrinkles.

Line with Velvet Attach Hardware

- Attach hinges, corner pieces, handles, and latches.

Attach Hardware

Read more: Deep Clean Your Case: A Step-by-Step Guide

Tips

- Pre-drill and countersink screw holes to avoid hitting screws when cutting the box.

- Avoid using screws where you plan to use a roundover bit. Remove screws and fill holes with wood filler before rounding over.

- Use a metal ruler to help when cutting foam.

- For best results when using spray adhesive, apply to both surfaces, let them dry, then adhere.

- Consider the type of corner pieces when selecting hardware. Sharp corners require different pieces than rounded corners.