Are your guitar's tuning pegs sticking, slipping, or simply worn out? Frustrating tuning issues can quickly derail your practice sessions and performances. Replacing your guitar's tuning machines, also known as tuners or machine heads, is a surprisingly straightforward task that can dramatically improve your playing experience. Whether you're dealing with vintage hardware that's seen better days or simply upgrading to a smoother, more reliable set, this project offers a satisfying blend of practicality and musical improvement. You'll gain a deeper understanding of your instrument's mechanics and achieve a more consistent, stable tuning.

This guide will walk you through the process of replacing your guitar's tuning machines, step-by-step. From preparing your tools and carefully removing the old tuners to installing the new ones and ensuring proper alignment, we'll cover everything you need to know to complete this essential maintenance or upgrade with confidence. Let's get started!

Preparation and Safety Guidelines

- Gibson SG Special guitar

- New tuning machines

- Screwdrivers

- Pencil

- Always use the correct size and type of tuning machine for your guitar. Using the wrong parts can damage your instrument.

- Before removing old tuners, take photos or make a detailed sketch of their positions and wiring. This helps during reassembly.

- If you're uncomfortable working on your guitar, take it to a qualified guitar technician. Improper installation can lead to tuning instability or damage.

Step-by-Step Instructions

String Removal

- Remove the strings from the guitar. Avoid cutting them to save as spares.

String Removal Remove Old Tuning Machines

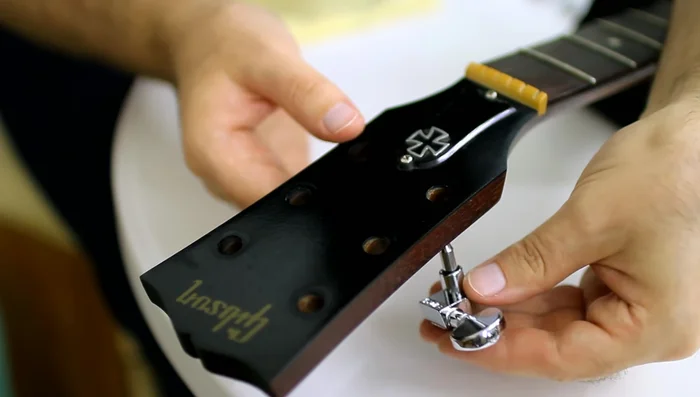

- Remove the nuts from the back of the guitar headstock by unscrewing them.

- Remove the old tuning machines.

Remove Old Tuning Machines Prepare for New Machines

- Choose new tuning machines that match the hole size and screw placement of your guitar.

- Clean the guitar headstock and fretboard.

Prepare for New Machines Install New Tuning Machines

- Insert the new tuning machines, ensuring not to overtighten them.

- Secure the new tuning machines using screws.

Install New Tuning Machines String Reinstallation

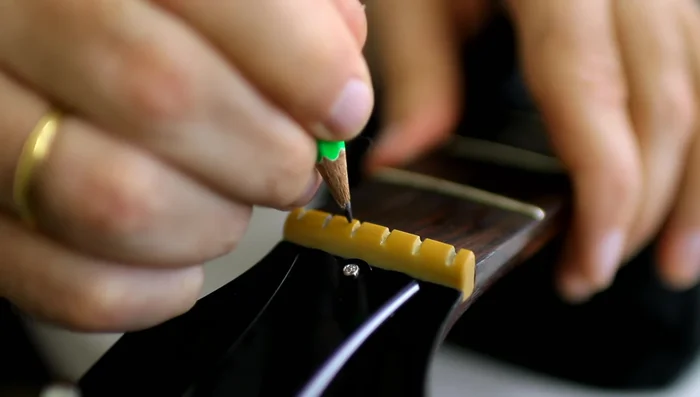

- Apply a small amount of pencil lead to the nut place before installing the locking nuts.

- Reinstall the strings, avoiding winding them around the peg too many times.

String Reinstallation

Read more: Fixing Loose Acoustic Guitar Tuners: The Toothpick & Glue Method

Tips

- Save old strings as spares.

- Ensure new tuning machines have the same hole diameter as the old ones.

- Don't overtighten the tuning machines.

- Use a small amount of pencil lead on the nut to aid in tuning stability.

- Avoid winding strings around the peg too many times for better tuning.