Open gear tuning machines, while offering a satisfyingly direct feel and often a more robust build than enclosed counterparts, require regular maintenance to ensure their smooth operation and longevity. Neglecting these crucial components can lead to frustrating tuning difficulties, inaccurate intonation, and even potential damage to your instrument. The intricate workings of these machines, exposed as they are, are susceptible to dust, grime, and the damaging effects of humidity, making preventative care essential.

This vulnerability, however, doesn't mean that keeping your open gear tuners in top condition is a daunting task. In fact, with a few simple steps and regular attention, you can easily prolong their life and maintain their precise performance. Let's delve into a straightforward, step-by-step guide that will equip you with the knowledge and techniques needed to keep your open gear tuning machines functioning flawlessly.

Preparation and Safety Guidelines

- Guitar

- Ear swab/Toothpick

- Petroleum jelly

- Clean Q-tip

- Always disconnect power to the tuning machine before performing any maintenance or cleaning. Failure to do so could result in electric shock.

- Use appropriate personal protective equipment (PPE), including safety glasses, when cleaning or handling open gear tuning machines. Moving parts and potential for debris can cause eye injuries.

- Never attempt to lubricate or repair the tuning machine if you are not familiar with its mechanics. Consult a qualified technician if unsure.

Step-by-Step Instructions

Preparation

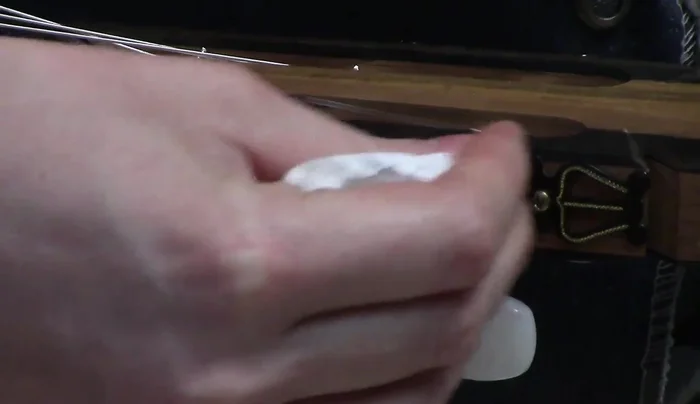

Applying Petroleum Jelly

- Use an ear swab or toothpick to apply the petroleum jelly.

- Run the swab/toothpick along the moving parts of the tuning machines.

- Apply petroleum jelly under the tuning machine as well.

- Move the swab/toothpick back and forth to distribute the petroleum jelly.

Applying Petroleum Jelly Testing and Adjustment

- Ensure full turn of the tuning machines after application.

Testing and Adjustment Cleaning Up

- Wipe off excess petroleum jelly to avoid transferring to hands or guitar finish.

- Use a clean Q-tip to mop up any residual petroleum jelly.

Cleaning Up

Read more: Fixing Loose Acoustic Guitar Tuners: The Toothpick & Glue Method

Tips

- For heavily rusted or gunked-up machines, remove the strings, soak in a cleaning solution, and then lubricate.

- Focus petroleum jelly application on moving parts (metal to metal) only to avoid getting it on the finish.

- Toothpicks with holes on one side are helpful for applying lubricants.