Tired of your guitars leaning precariously against walls or crammed into cluttered cases? Do you crave a stylish and functional guitar stand without the hefty price tag of store-bought options? Then you've come to the right place! This guide will show you how to construct a robust and attractive 6-guitar stand using only a quarter sheet of MDF and a few readily available tools. We'll bypass complex joinery and focus on a design that prioritizes simplicity, sturdiness, and ease of construction, even for beginner DIY enthusiasts.

Forget expensive, complicated plans; this project is designed for efficiency and practicality. You'll be amazed at how easily you can transform a seemingly humble sheet of MDF into a custom-built stand perfect for your collection. Ready to get started on building your own amazing guitar stand? Let's dive into the step-by-step instructions!

Preparation and Safety Guidelines

- MDF or plywood

- adhesive-backed vinyl or paper template and spray adhesive

- straight edge

- circular saw

- jigsaw

- hole saw bit

- drill

- bandsaw

- sandpaper

- screws

- clamps

- paint (optional)

- foam tape (optional)

- razor (optional)

- Always wear safety glasses when cutting and sanding MDF. Dust and flying debris can cause eye injuries.

- Use appropriate clamps to secure the MDF during cutting and assembly to prevent injury and ensure accurate cuts.

- Ensure all screws are properly tightened to prevent the stand from collapsing and damaging your guitars.

Step-by-Step Instructions

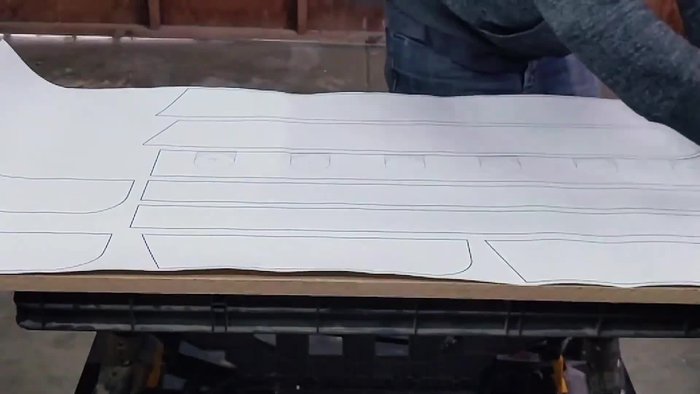

Prepare and Cut MDF

- Prepare the template and cut the MDF.

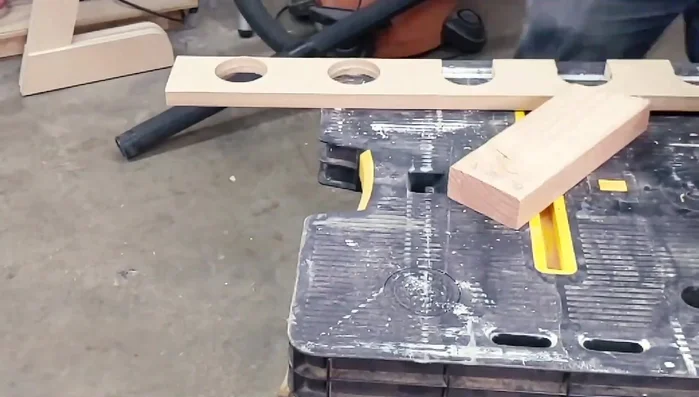

Prepare and Cut MDF Drill Neck Rest Holes

- Drill holes for the neck rest using a hole saw bit.

Drill Neck Rest Holes Bandsaw Cut and Initial Shaping

- Use a bandsaw to cut along the lines, leaving slightly outside the line for sanding.

Bandsaw Cut and Initial Shaping Sand and Remove Template

- Remove the template and sand all matching pieces together until smooth.

Sand and Remove Template Assemble Legs and Uprights

- Assemble the legs and upright piece using screws.

Assemble Legs and Uprights Cut Neck Rest Openings

- Cut out the neck rest holes with a jigsaw.

Cut Neck Rest Openings Sand Neck Rest

- Sand the inside and edges of the neck rest.

Sand Neck Rest Attach Neck Rest to Uprights

- Attach the neck rest to the uprights, pre-drill, and screw them together.

Attach Neck Rest to Uprights Attach Body Supports

- Attach the front support for the guitar bodies. Pre-drill holes and attach the body rest piece from both sides.

Attach Body Supports Final Assembly and Alignment

- Assemble the remaining parts, checking alignment before permanently attaching.

Final Assembly and Alignment Final Sanding

- Sand down all edges and corners for a smooth finish.

Final Sanding Painting and Padding (Optional)

- Paint (optional) and add foam padding to the body rests and neck pockets.

Painting and Padding (Optional)

Read more: 3D Printed Hercules Guitar Stand Handle Repair: A Durable Fix

Tips

- Using a jigsaw after rough cutting with a circular saw provides a cleaner cut.

- Sanding matching pieces together ensures symmetry.

- Pre-drilling holes before screwing prevents splitting the wood.

- Using clamps ensures proper alignment while screwing.